Some Known Questions About Motorcycle Boots.

Table of ContentsWhat Does Motorcycle Boots Do?Motorcycle Boots Fundamentals ExplainedMore About Motorcycle Boots9 Easy Facts About Motorcycle Boots ShownFacts About Motorcycle Boots UncoveredThe Definitive Guide to Motorcycle Boots

: From navigation to emergency situation contacts if you obtain stranded or fall, a smartphone is going to be exceptionally valuable. Maintain it with you when you ride. As for devices for your bike that depends greatly on what your bike is and what you intend on finishing with it. There are great deals of points most motorcyclists may not think of tackling a lengthy motorcycle trip.For long experiences, the prolonged noise can become a problem and even an illness. Some simple hearing security like ear plugs will mute the wind while leaving you able to listen to car horns and other louder noises.: Breaking down a lengthy way from home can be stressful. You'll have no concept who to call or just how to locate their get in touches with.

Every season positions its very own obstacles to bikers::: Dirtbiker shield contains sturdy armor pads integrated with a mesh t shirt keeping it all with each other. While they provide inferior rough protection for high-speed spills, they supply exceptional effect and low-speed defense. And also, they can't be beat when it comes to air flow.

The 6-Second Trick For Motorcycle Boots

That's not just a deluxe cool cyclists will be less responsive, and chilly fingers will certainly be slow-moving on the brake, clutch and throttle.: Ice and snow are twice as hazardous for bikes. We've only got two tires, not 4, and ours are narrow. If there's ice and snow on the ground and you can not remain home metal-spiked tires are best, and knobby off road tires can be found in a distant second location.

Yet within the plastics market, there are several products to take into consideration, each with unique benefits. Below is a better take a look at the most effective plastic for motorcycle components and exactly how plastics are improving the automotive industry. Plastics have had a fundamental function in the advancement of the automobile sector. Today, roughly one-third of all components in a vehicle is plastic.

The lighter a motorbike or various other lorry is, the less fuel it takes to run and the quicker it can travel. Producing lightweight products without sacrificing the toughness of those products is a crucial goal of the vehicle producer, and plastics permit this. Plastics call for less energy to generate than steel.

It additionally provides toughness and electrical insulation, often used for front lights lenses. Producers utilize it for fairings and dashboards on motorbikes. Manufacturers may utilize it for seats and trims on bikes.

Facts About Motorcycle Boots Revealed

Abdominal adds the rigidity and toughness of styrene and acrylonitrile with the flexibility of butadiene rubber to produce a versatile and light-weight polymer material. It withstands heat well, also, and can can be found in a variety of shades to match any type of search for a bike. The material experts at Piedmont Plastics prepare to help you locate the very best materials for your bike component making requirements.

So, connect to among our professionals today.

Motorcycle Boots Things To Know Before You Buy

Businesses need to take into consideration CNC machining for making personalized motorbike accessories for the following factors: Machining bike parts is specific and exact. Consequently, it is highly suitable for parts where mistakes in part dimensions can lead to substantial problems. The accuracy makes sure consistency and harmony of parts throughout production.

Therefore, it is ideal for difficult products, whether plastics, metals, and some composite find this materials. Producers have a high level of freedom when picking materials, regardless of motorcycle versions and styles. CNC machining is a reliable process that can create custom motorbike components rapidly, making it ideal for both one-off productions and small production runs

Unlike various other metal manufacturing processes, sheet metal fabrication generates little waste. As a result, there is a reduction in the expense of buying products and the result on the atmosphere.

Common custom bike devices produced using sheet metal manufacture consist of: Sheet steel construction is suitable for creating gas containers of various dimensions and shapes. Fenders for customized motorcycle parts with both functional and visual objectives.

The Greatest Guide To Motorcycle Boots

3D printing is the most suitable technique for prototyping, especially during the experimental phase, as developers can promptly repeat and refine their layouts without throwing away time and products. 3D printing, due to the layering technique, permits the production of hollow parts quickly, making it ideal for making parts that urge reduced gas usage.

As soon as a mold, succeeding components can be produced with lowered per-unit prices. There is high consistency and accuracy when dealing with injection molding. As a result, each part is identical to the various other. This is highly crucial in crucial elements that are put together after manufacturing. Injection molding is perfect for parts that need high customization as structural parts. motorcycle boots.

Their cost-effectiveness allows the manufacture of these components for resale to a more comprehensive market. When the mold and mildew is prepared, the injection molding process is quick, with cycle times generally ranging from secs to mins. This quick turnaround is beneficial when satisfying tight job target dates. Shot molding applies in making the following bike body parts.

The Buzz on Motorcycle Boots

For simple parts, injection molding or sheet steel fabrication is much better. Apart from choosing the try this site performance and appearances of custom motorcycle components, the choice of material likewise identifies the review production process.

Injection molding and sheet metal fabrication are much more economical for high-volume manufacturing. The cost of devices can also establish the price of personalized bike building. The majority of services in bike component constructing outsource their task to quick prototyping and manufacturing solutions as a result of the need to prevent the high financial investment expense and still have accessibility to various devices.

Alana "Honey Boo Boo" Thompson Then & Now!

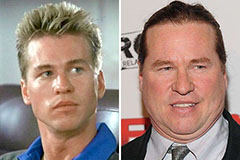

Alana "Honey Boo Boo" Thompson Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Ashley Johnson Then & Now!

Ashley Johnson Then & Now! Danielle Fishel Then & Now!

Danielle Fishel Then & Now! Atticus Shaffer Then & Now!

Atticus Shaffer Then & Now!